Current location:

Links:

-

Ultimately, navigating the thin metal stakes of innovation requires a blend of courage, insight, planning, and flexibility. It demands a willingness to take calculated risks and an unwavering commitment to learning and adapting in the face of adversity. As the business environment continues to evolve at a breakneck pace, those who can successfully walk these tightropes will be the ones who shape the future. Iron barbed wire, a classic symbol of security and protection, has been used for centuries to deter intruders and mark boundaries. Its sharp barbs and intimidating appearance have made it an effective tool for safeguarding properties, farms, and communities. The cost of repairing cavity wall tie failure can vary depending on the extent of the damage and the size of the building. In general, the cost of repairing cavity wall tie failure can range from a few thousand dollars to tens of thousands of dollars. This cost includes not only the replacement of the failed wall ties but also the necessary structural repairs to ensure the stability of the building. Fencing also affects the efficiency of land use. By enabling rotational grazing and effective land management, it allows for better grass utilization and soil health, which can lead to increased productivity over time. Thus, when viewed through this lens, the cost of cattle fencing is not merely an expense but rather an integral component of sustainable farming practices. Lastly, the environment, as an intangible h% stakeholder, has gained increasing attention. With growing concerns over climate change, companies must consider their ecological footprint and strive for sustainable practices. Failure to do so could result in regulatory penalties, reputational damage, and loss of investor confidence. PVC coated galvanized wire is also highly flexible and easy to install

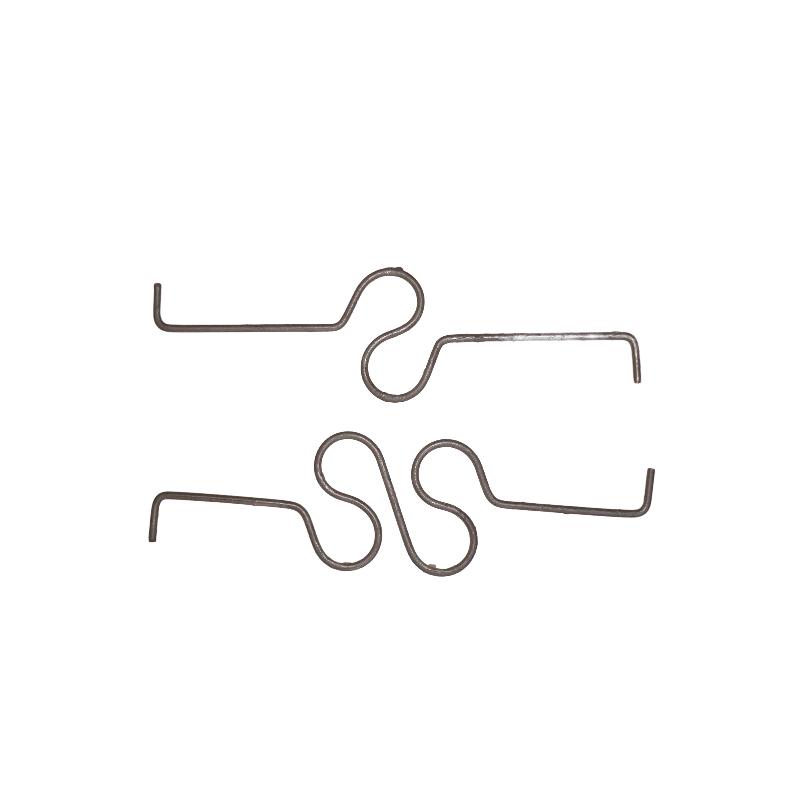

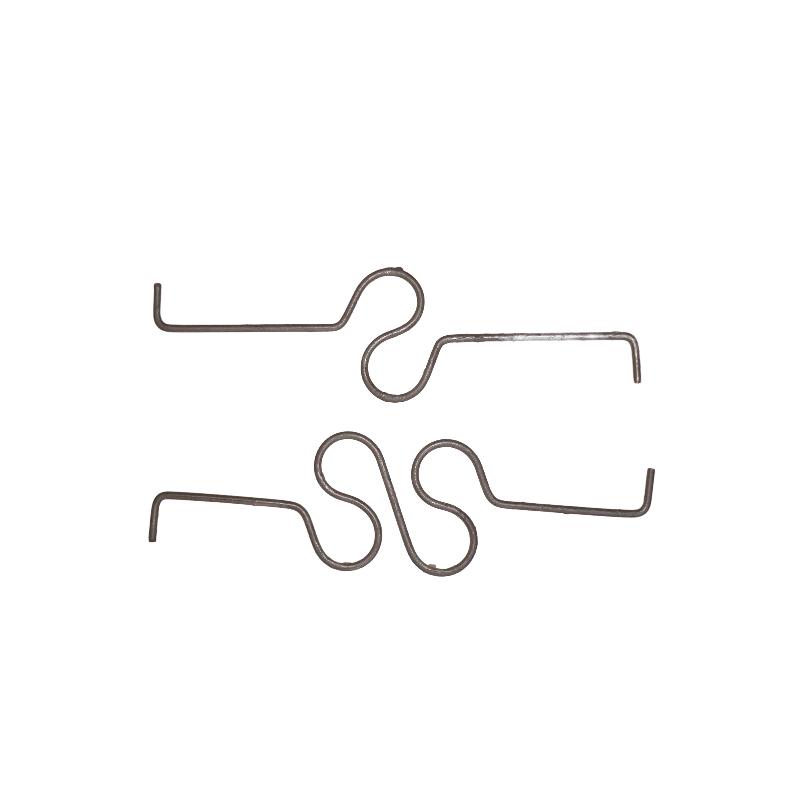

Bulk compression springs are typically made from high-strength steel wires, formed into coiled shapes with open coils to allow for linear compression. The design of these springs is versatile, ranging from simple cylindrical forms to more complex configurations like conical, helical, or even variable pitch, depending on the specific application requirements. Their unique feature lies in their ability to store mechanical energy when compressed and release it when the load is removed, making them ideal for applications where shock absorption or force resistance is necessary. 1. Prepare the work area Ensure that the area where the cavity wall ties will be installed is clean and free of debris. Remove any loose mortar or debris from the joints between the inner and outer walls. 1. Choose the Right Cage There are several types of tomato cages available, including metal cages, wooden stakes, and DIY options made from wire mesh. Choose a cage that is sturdy and tall enough to support your tomato plants as they grow. ``` Despite its many benefits, the maintenance of a galvanized wire fence is relatively low. Regular cleaning to remove dirt and debris is usually sufficient, with occasional touch-ups of the zinc coating if needed. This low maintenance requirement further contributes to its overall cost-effectiveness. A helical spring, as the name suggests, is a spiral-shaped object made from a wire or rod material, typically steel. The helical structure is derived from the coiled shape that the material assumes when bent into a circular pattern. This design allows the spring to store and release mechanical energy efficiently. The Utility Extension Spring also finds extensive use in the automotive industry, where they are used in seat mechanisms, hood latches, and window regulators. In the aerospace sector, they are employed in various aircraft components due to their ability to operate under extreme conditions. The medical industry also harnesses their potential, using them in surgical instruments and medical device mechanisms. Moreover, the wholesale market for iron wire fosters economic growth. It creates job opportunities in mining, processing, manufacturing, and distribution. It also contributes to international trade, with countries exporting and importing iron wire to balance their supply and demand. The competitive pricing in the wholesale market stimulates competition, leading to improved product quality and efficiency. China, the world's manufacturing hub, is home to numerous wire mesh manufacturers who cater to global demands with their high-quality products and competitive pricing. Wire mesh, an essential material used in various industries from construction to filtration, is a testament to Chinese manufacturing prowess. The term flat rib metal lath refers to its unique design, characterized by its flat, ribbed profile. The ribs, which are typically made from steel or aluminum, increase the tensile strength of the lath, allowing it to withstand the stresses imposed during the application and curing process of plaster or stucco. The spacing between these ribs allows for an even distribution of the finishing material, ensuring a smooth and consistent finish. The Versatile Use of 6 ft Metal Stakes in Various Applications 1 Some of the key areas where these springs are used include Are you in the market for a new field fence to enhance the security and beauty of your property? Look no further! We are proud to offer a wide selection of high-quality field fences for sale, designed to meet the unique needs of our customers. Step 4 Position the Cage Brick ties, as the name suggests, are metallic or plastic connectors that bind the inner and outer leaves of a cavity wall together. They are available in various sizes, with the 250mm brick tie being a standard option. The '250mm' refers to the overall length of the tie, which includes the portion that extends into the cavity and the part that protrudes out for fixing to the bricks. Black iron wire is a versatile and durable material that is widely used in various industries, including construction, agriculture, and crafts. Made from low-carbon steel and coated with a layer of black oxide, black iron wire is known for its strength, flexibility, and resistance to corrosion. In conclusion, the 6ft welded wire fence represents a reliable and economical choice for those seeking a strong and enduring enclosure system. Its ability to adapt to various environments and purposes, coupled with minimal upkeep requirements, makes it a smart investment for properties of all sizes. With proper installation and basic maintenance, a welded wire fence promises years of service, enhancing security and adding value to any property it surrounds.

Bulk compression springs are typically made from high-strength steel wires, formed into coiled shapes with open coils to allow for linear compression. The design of these springs is versatile, ranging from simple cylindrical forms to more complex configurations like conical, helical, or even variable pitch, depending on the specific application requirements. Their unique feature lies in their ability to store mechanical energy when compressed and release it when the load is removed, making them ideal for applications where shock absorption or force resistance is necessary. 1. Prepare the work area Ensure that the area where the cavity wall ties will be installed is clean and free of debris. Remove any loose mortar or debris from the joints between the inner and outer walls. 1. Choose the Right Cage There are several types of tomato cages available, including metal cages, wooden stakes, and DIY options made from wire mesh. Choose a cage that is sturdy and tall enough to support your tomato plants as they grow. ``` Despite its many benefits, the maintenance of a galvanized wire fence is relatively low. Regular cleaning to remove dirt and debris is usually sufficient, with occasional touch-ups of the zinc coating if needed. This low maintenance requirement further contributes to its overall cost-effectiveness. A helical spring, as the name suggests, is a spiral-shaped object made from a wire or rod material, typically steel. The helical structure is derived from the coiled shape that the material assumes when bent into a circular pattern. This design allows the spring to store and release mechanical energy efficiently. The Utility Extension Spring also finds extensive use in the automotive industry, where they are used in seat mechanisms, hood latches, and window regulators. In the aerospace sector, they are employed in various aircraft components due to their ability to operate under extreme conditions. The medical industry also harnesses their potential, using them in surgical instruments and medical device mechanisms. Moreover, the wholesale market for iron wire fosters economic growth. It creates job opportunities in mining, processing, manufacturing, and distribution. It also contributes to international trade, with countries exporting and importing iron wire to balance their supply and demand. The competitive pricing in the wholesale market stimulates competition, leading to improved product quality and efficiency. China, the world's manufacturing hub, is home to numerous wire mesh manufacturers who cater to global demands with their high-quality products and competitive pricing. Wire mesh, an essential material used in various industries from construction to filtration, is a testament to Chinese manufacturing prowess. The term flat rib metal lath refers to its unique design, characterized by its flat, ribbed profile. The ribs, which are typically made from steel or aluminum, increase the tensile strength of the lath, allowing it to withstand the stresses imposed during the application and curing process of plaster or stucco. The spacing between these ribs allows for an even distribution of the finishing material, ensuring a smooth and consistent finish. The Versatile Use of 6 ft Metal Stakes in Various Applications 1 Some of the key areas where these springs are used include Are you in the market for a new field fence to enhance the security and beauty of your property? Look no further! We are proud to offer a wide selection of high-quality field fences for sale, designed to meet the unique needs of our customers. Step 4 Position the Cage Brick ties, as the name suggests, are metallic or plastic connectors that bind the inner and outer leaves of a cavity wall together. They are available in various sizes, with the 250mm brick tie being a standard option. The '250mm' refers to the overall length of the tie, which includes the portion that extends into the cavity and the part that protrudes out for fixing to the bricks. Black iron wire is a versatile and durable material that is widely used in various industries, including construction, agriculture, and crafts. Made from low-carbon steel and coated with a layer of black oxide, black iron wire is known for its strength, flexibility, and resistance to corrosion. In conclusion, the 6ft welded wire fence represents a reliable and economical choice for those seeking a strong and enduring enclosure system. Its ability to adapt to various environments and purposes, coupled with minimal upkeep requirements, makes it a smart investment for properties of all sizes. With proper installation and basic maintenance, a welded wire fence promises years of service, enhancing security and adding value to any property it surrounds. Weldmesh suppliers play a crucial role in providing high-quality materials to construction companies, contractors, and DIY enthusiasts alike. By sourcing weldmesh from reputable suppliers, you can ensure that your project will be built on a strong foundation that will stand the test of time

weldmesh suppliers. Furthermore, chicken wire mesh can be used for various DIY projects and crafts. Its malleable nature allows for easy shaping and manipulation, making it a versatile material for creating decorative items, such as lampshades, planters, and sculptures. One of the primary advantages of PVC coated iron wire is its corrosion resistance. Since iron is prone to rusting when exposed to moisture and oxygen, the PVC coating acts as a protective barrier, preventing rust from forming. This makes the wire suitable for use in harsh environments where exposure to moisture and corrosive substances is common, such as construction sites, marine environments, and agricultural settings. Wire mesh manufacturers play a pivotal role in shaping the world around us. They are the architects of a product that, while often unseen, significantly contributes to infrastructure, safety, and efficiency. These manufacturers specialize in the production of wire mesh, a woven or welded grid made from various metals, including steel, aluminum, copper, and stainless steel, among others. **The Concept of White Grid 5. Surface Treatment Apply a surface treatment to enhance the spring's durability and fatigue life, such as plating or coating.

In addition to preventing cracks, stucco diamond mesh also helps to improve the overall strength of the stucco surface. The mesh is embedded in the base coat of the stucco and acts as a reinforcement, adding structural support to the wall. This extra strength is especially beneficial in areas prone to seismic activity or high winds, where additional stability is needed to prevent damage.

stucco diamond mesh

Seismic load: The external force exerted on a building structure by the vibration caused by an earthquake.

Expansion Ties In agriculture, weld mesh sheets serve as livestock enclosures, offering safety and protection while allowing for visibility and air circulation. They are also employed in erosion control projects, forming part of gabion baskets or rockfall protection barriers. In addition, these fence panels can be further enhanced with various toppings such as razor wire or barbed wire for added security. They can also be painted in different colours to blend seamlessly with the surroundings or to create a distinctive look. Welded wire mesh, an essential material in various industries, is currently available for sale, offering a versatile solution to construction, agriculture, and manufacturing needs. This robust and durable product is known for its strength, flexibility, and ease of installation, making it a popular choice worldwide. Sign holders, often made from materials like plastic, metal, or wood, serve a multitude of purposes. They are used in retail stores to advertise sales, in restaurants to display menus, in exhibitions to highlight products, and even in public spaces to convey important messages. Their versatility lies in their ability to adapt to any environment, making them a staple in various industries. In conclusion, an 8 chain link fence is more than just a physical boundary; it's a reliable solution that harmoniously combines form and function. As we navigate through the evolving world of fencing options, the charm and utility of this classic choice remain undiminished, continuing to serve its purpose with unwavering efficiency. For more intricate tasks, such as shaping topiary or forming wire frames for hanging baskets, strong garden wire proves equally efficient Chicken wire also provides excellent support for hanging floral designs When shopping for affordable tomato cages, consider durability as a primary factor. Look for cages made from galvanized steel or heavy-duty plastic, materials that can withstand the rigors of weather and the weight of the plants. These materials not only ensure longevity but also maintain their structural integrity throughout the growing season. Chain link fences are a common sight in many residential and commercial properties. These fences are made up of interlocking metal links that create a sturdy and durable barrier. One popular version of chain link fences is the 6% chain link fence, which offers a balance between security and visibility. One of the key advantages of plaster beading is its versatility. It can be used to create a wide range of designs, from simple geometric patterns to more complex floral or animal motifs. The material itself is also quite forgiving, allowing artists to make adjustments and corrections as needed. 3. Thermal and Moisture Barriers Rib lath stainless steel can also be used as a thermal and moisture barrier in building envelopes, helping to improve energy efficiency and durability. One of the key benefits of using an external corner bead is its ability to improve the overall structural integrity of the plasterboard. Corners are naturally vulnerable points in any construction, and the addition of a corner bead significantly increases their resistance to cracking and splitting. Furthermore, it saves time and money in the long run by reducing the need for repairs. At its core, woven steel mesh is a product of precision engineering. It is created by weaving steel wires together, either by a plain weave, twill weave, or dutch weave, depending on the intended use and desired properties. The weaving process ensures that the mesh maintains a consistent pattern, providing both stability and flexibility, which is crucial for various applications. Additionally, expansion ties can bring fresh perspectives and ideas to the table expansion ties. By interacting with people from different backgrounds, cultures, and industries, individuals and organizations can gain new insights and approaches to their work. This can lead to more effective decision-making, problem-solving, and overall growth. One of the key benefits of a 6ft welded wire fence is its adaptability. It can be installed on uneven terrains, around corners, and over large expanses with relative ease. The mesh size can also be customized based on the specific needs, such as keeping smaller animals in or larger ones out. Additionally, the fence can be electrified or combined with other materials like wooden posts for added strength and aesthetic appeal Additionally, the fence can be electrified or combined with other materials like wooden posts for added strength and aesthetic appeal

expansion ties. By interacting with people from different backgrounds, cultures, and industries, individuals and organizations can gain new insights and approaches to their work. This can lead to more effective decision-making, problem-solving, and overall growth. One of the key benefits of a 6ft welded wire fence is its adaptability. It can be installed on uneven terrains, around corners, and over large expanses with relative ease. The mesh size can also be customized based on the specific needs, such as keeping smaller animals in or larger ones out. Additionally, the fence can be electrified or combined with other materials like wooden posts for added strength and aesthetic appeal Additionally, the fence can be electrified or combined with other materials like wooden posts for added strength and aesthetic appeal Additionally, the fence can be electrified or combined with other materials like wooden posts for added strength and aesthetic appeal Additionally, the fence can be electrified or combined with other materials like wooden posts for added strength and aesthetic appeal

Additionally, the fence can be electrified or combined with other materials like wooden posts for added strength and aesthetic appeal Additionally, the fence can be electrified or combined with other materials like wooden posts for added strength and aesthetic appeal welded wire fence 6ft. In interior design, these panels serve multiple purposes. They can be used as room dividers, creating a visually appealing separation without obstructing light flow. Their open structure allows for air circulation, making them ideal for use in areas where ventilation is crucial. They can also double as wall art, adding depth and texture to an otherwise flat surface. The versatility of gold metal grid panels extends to their ability to complement various design styles, from minimalist chic to Art Deco grandeur. It is important to choose the right timber frame ties for a specific project to ensure that the structure is safe and secure. Factors such as the size of the timbers, the weight of the structure, and the location of the project should all be taken into account when selecting timber frame ties. Consulting with a structural engineer or timber frame specialist can help to determine the best type of ties to use for a specific project.

welded wire fence 6ft. In interior design, these panels serve multiple purposes. They can be used as room dividers, creating a visually appealing separation without obstructing light flow. Their open structure allows for air circulation, making them ideal for use in areas where ventilation is crucial. They can also double as wall art, adding depth and texture to an otherwise flat surface. The versatility of gold metal grid panels extends to their ability to complement various design styles, from minimalist chic to Art Deco grandeur. It is important to choose the right timber frame ties for a specific project to ensure that the structure is safe and secure. Factors such as the size of the timbers, the weight of the structure, and the location of the project should all be taken into account when selecting timber frame ties. Consulting with a structural engineer or timber frame specialist can help to determine the best type of ties to use for a specific project.